What is torque and why is it important for a tool?

What is meant by torque

In simple terms, without much physics, torque can be characterized as the force that rotates the output shaft of the tool. The more torque, the more force on the shaft, the greater the ability to withstand heavy loads, the better the tool can cope with the resistance of the material being worked on.

Torque is quantified in Newton meters, representing the rotational force generated when applying a 1 N force at the end of a 1 m lever.

Considering that 1 N is approximately equal to 100 g, a torque of 30 Nm (a notable feature in a good screwdriver) implies that the tool's electric motor, transmitted via gears, exerts a force on the output shaft equivalent to the effect of a 3 kg weight on a 1 m long lever.

|

| Torque can be clearly demonstrated in this way. |

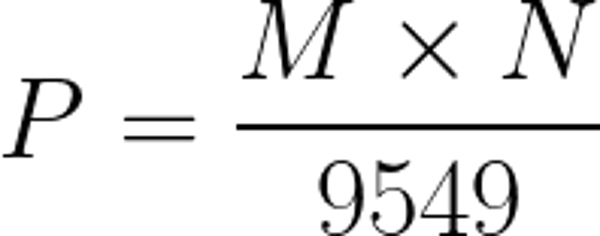

Recognizing the significance of torque in motors, whether for of power tools or vehicles, is straightforward when considering its inclusion in the motor power formula. Torque plays an equally crucial role as rotation speed in determining overall power.

|

| Formula for calculating power depending on torque and rpm. |

The formula above includes the characteristics at the output shaft:

- P is the power in kilowatts (kW);

- M is the torque in Newton meters (Nm);

- N is the rotation speed in revolutions per minute (rpm).

Screwdriver torque

The theory may seem confusing or not entirely obvious. The meaning of torque will be easier to understand by looking at the practical aspects. Take, for example, screwdrivers — tools for which torque is one of the key parameters (it is necessarily indicated in the technical specifications of each model).

In the case of a screwdriver, torque can be figuratively described as the force with which the tool can turn the attachment (bit or drill). This characteristic determines what resistance the screwdriver can overcome and what work can be performed with its help.

- 4 – 5 Nm – this force approximately corresponds to the screw tightening force that can be achieved using a conventional hand screwdriver. Cordless electric screwdrivers usually have approximately the same torque;

- 15 – 20 Nm – this torque value is usually used by tools designed for tightening small screws when installing drywall or plywood on a metal profile frame;

- 30 – 50 Nm – typical characteristics for a universal screwdriver, allowing you to screw medium-sized screws (up to 5 – 6 mm in diameter and up to 70 – 80 mm in length) into plastic dowels or non-hardwood;

- 75 – 100 Nm – torque of powerful tools that are used by professional builders and installers to drill holes for brackets and work with large fasteners;

- 100 Nm – 200 Nm – a very high tightening force, which is found exclusively in impact screwdrivers. These torque levels enable the secure fastening of substantial screws, such as large 15 — 25 cm ones used for connecting beams in wooden structures. It's important to note that a tool with a torque exceeding 100 Nm has the potential to snap a medium-quality bit in half. To address this, users often opt for specialized "impact-rated" attachments designed for use with these high-torque screwdrivers.

It should be noted that high torque is not needed for all tasks. Therefore, almost every screwdriver is equipped with an adjustment clutch that changes the tightening force. As a rule, it has 15 — 20 positions — quite enough to customize the tool for working with one or another material. By rotating the adjuster knob, it is possible to change the torque value at which the clutch will disengage the chuck from the gear. Thanks to the ability to adjust the force, the same screwdriver can be used to tighten screws and self-tapping screws into different materials: from soft ones, which are easily damaged if handled carelessly, to hard and dense ones.

|

| Drill driver with clutch for adjusting torque. |

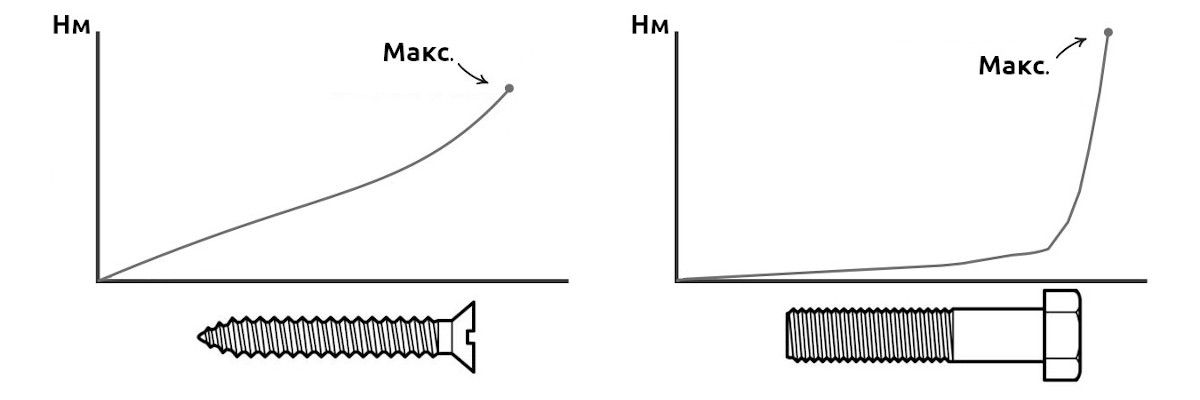

Hard and soft torque

Some power tool manufacturers show off the high torque value of their screwdrivers, but do not like to go into details. Other companies (as a rule, the more famous and reputable ones) specify hard and soft torque separately in the operating manual. Many users have questions: what is the difference between hard and soft torque, and how do these characteristics affect the performance of the screwdriver? Let us try to explain briefly.

- Hard torque refers to short-term, peak torque value encountered during specific work scenarios. For instance, when using a screwdriver to fasten a screw into a threaded hole in a metal part, the tool may effortlessly navigate the thread until it suddenly encounters resistance upon reaching the end. This momentary, intense force, lasting only a fraction of a second, as the tool contends with reaching the final position, is what we define as hard torque.

- Soft torque is a measurable force encountered during prolonged processes. To illustrate, consider the scenario of driving a long self-tapping screw into wood using a screwdriver. Initially, the process is smooth, but as the screw progresses millimeter by millimeter into the wood, the strain on the screwdriver intensifies. Eventually, there comes a point where the tool halts, lacking the strength to continue screwing in the fastener. This represents soft torque, a force achieved through a gradual and steady increase in load.

The graphs below clearly show how the torque required to screw fasteners into soft materials (wood) and hard materials (metal) increases. The graphs clearly show that the soft torque is always less than the hard torque. Therefore, it is not surprising that many manufacturers in the characteristics of the tool specify only the higher number corresponding to the hard torque. Nevertheless, specifically for a screwdriver (a tool originally designed for screws and self-tapping screws) the more important parameter is the soft torque, as it more objectively shows the capabilities of a particular model. Therefore, when choosing a screwdriver, you should pay attention not only to the passport characteristics, but also look at the operating manual, watch videos with reviews or read reviews — look for additional information that reveals in more detail the capabilities of a particular tool.

|

| Increase curves of torque: on the left — when screwing a self-tapping screw into wood, on the right — when screwing a screw into a metal workpiece. |

Impact wrench torque

But for impact wrenches, unlike screwdrivers, the hard torque exactly is important — the peak force required to tighten a fastener as tightly as possible or to loosen a connection that has become stuck due to corrosion. The higher the tightening force, the more difficult tasks can be accomplished with the impact wrench.

- 150 Nm – 200 Nm – this torque is quite enough to unscrew and tighten the wheel bolts that hold the wheels of a regular passenger car, without fear of damaging the threads.

- 250 Nm – 300 Nm are normal characteristics for a universal impact wrench that is used in a garage or a small car service center. This torque is enough not only to work with wheel bolts, but also to unscrew a hub nut or to remove corroded fasteners up to M20.

- 500 Nm – 1000 Nm – that's how much torque is needed for tools used to repair trucks and special vehicles or to assemble and disassemble metal structures.

Since too much force can damage fasteners or strip threads, the gears of powerful impact wrenches usually have several speeds (at least 2 – 3, but in some cases up to 5 – 6), which differ in torque – this makes it possible to select the optimal one mode for working with fasteners of a certain size.

What about other instruments?

Other power tools, except screwdrivers and impact wrenches, cannot boast the ability to adjust the torque on the output shaft. But for some of them, torque is also important (to varying degrees). For example, the drill must have enough torque so that there is no drop in speed when the load increases, and to make it possible to use large-diameter tools (feather drill bits, Forstner drills, ring bits, etc.). With concrete mixers and plaster mixers, the moment determines whether the equipment can turn over and mix concrete and building mixtures. And for a circular saw or wall chaser, the output force on the shaft determines whether the tool can cope with heavy loads, overcoming the resistance of the material being cut.

Brief summary

As demonstrated above, torque is important for many types of power tools and construction equipment. As a general rule, the more torque — the more possibilities. But sometimes the force on the output shaft can be excessive (a tool with too high torque can break threads or drive a screw through a board). For this reason, tools should always be tailored to the specific task or activity.

Articles, reviews, useful tips

All materials